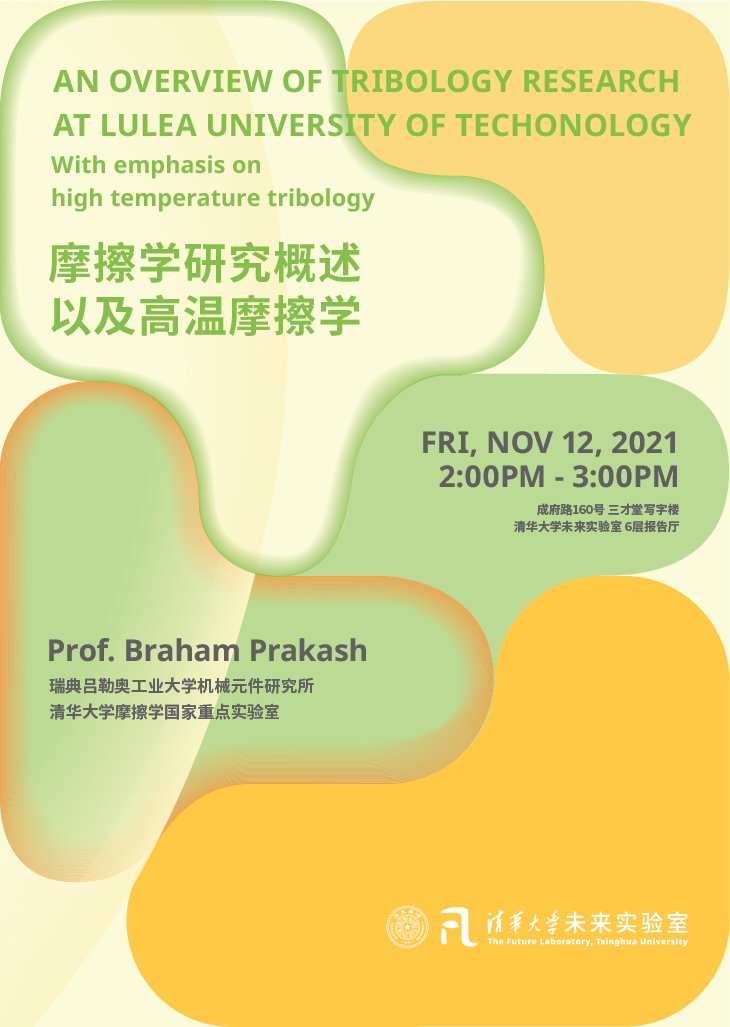

Braham Prakash

LECTURER

Braham Prakash obtained his M.Tech (Mechanical Engineering) and PhD (Tribology) degrees from Indian Institute of Technology Delhi, India. He worked in industry for about five years and then took up a faculty position at Indian Institute of Delhi in India and worked there up to 2002. He is presently a Professor and Head of Tribolab at the Division of Machine Elements of Luleå University of Technology in Sweden since January 2002. He was a Visiting Researcher Tokyo Institute of Technology (1985) and Fellow of Japan Society for the Promotion of Science (JSPS) at Chiba Institute of Technology (1998-2000). He has over 37 years of R&D experience both in academia and industry in the field of tribology. His research & teaching activities pertain to high temperature tribology; tribology of materials & lubricants; solid lubricants/self-lubricating coatings; boundary lubrication; tribology of machine components (bearings, gears and seals); analysis of wear problems; and tribotesting.

Summary

In the lecture, Prof.Braham first introduced the Luleå University of Technology(LUT) and the Mechanical Research Institute he worked. The mechanical research institute and its' tribology research in LUT have played an essential role in the field.

Tribology, a discipline that studies friction, lubrication, and wear between relative motion or interactive surfaces with relative motion trends, and the relationship among them. Tribology involves a wide range of fields. Many complex factors affect the performance of friction interface, including physics, mathematics, materials, etc.

Most of his researches are based on the industrial application. By pursuing the optimal scheme in tribology to reduce friction and wear, he aims to reduce the cost and energy consumption while improving product quality. He focuses on several of his projects, such as friction and wear problems in the hot pressing of ultra-high-strength steel and the development of lubricating coatings; Tribology in vehicle clutch; Tribology in engine cylinder liner, etc. On cutting-edge researches, prof.Braham introduces the multiscale polymer composites for water lubricated tribological contacts.